Training & Consulting Services

Stamping Press Operation & Die Setting Practices

This training program is ideally suited for onsite (in-plant) training but also is available virtually. It provides the fundamental principles for safe operation and setup of mechanical power presses and feed lines utilized in your plant.

Topics include press construction/components, drive system types (flywheel, servo, hydraulic), understanding tonnage ratings, the use of tonnage monitors, using press controls and operator controls, and point-of-operation safeguarding. Procedures provided for tailing out the end of a coil, safely loading a new coil, threading progressive dies, making straightening and feeding adjustments, and setting the slack loop.

Setup instruction includes removing, setting and clamping dies; understanding counterbalance settings; establishing feed angles and sensor windows; properly setting the pilot release; solder-check steps for final die shut height adjustment and troubleshooting setup problems.

Stamping Technology for Engineers & Managers

This program is available onsite or virtually. It is designed for employees directly and indirectly involved with the planning, estimating, and supervision of metal stamping processes and tooling projects.

Topics include the fundamental principles of metal stamping operations, including stamping presses, feed lines, die operations, sheet metal properties, deformation mechanics (drawing, forming, punching and blanking), evaluating progressive die strip layouts, identifying cost drivers, troubleshooting methodologies, and common metal stamping problems and solutions.

Deep Draw Processes & Die Design Guidelines

This training program is available onsite or virtually. It provides the fundamentals principles of deep drawing and redrawing cylindrical cups, boxes and advanced principles for drawing irregular and complex shapes.

Topics include estimating process costs; die design principles; the impact of material properties on die design and production; assessing press tonnage and press energy requirements; simulating deep drawing process and interpreting simulation results; troubleshooting and solving deep drawing process problems.

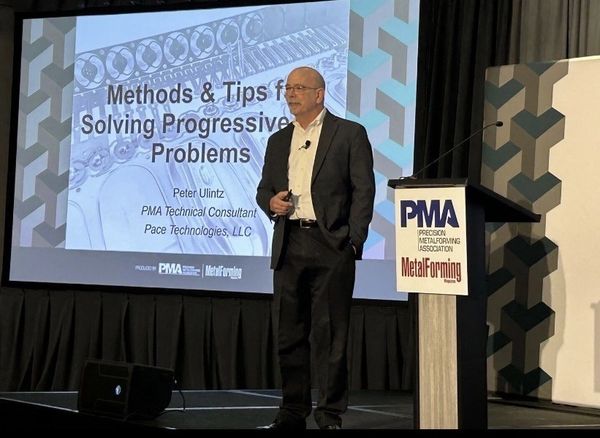

Speaking and Consulting Services

TOOL & DIE TECHNOLOGY

Progressive Die Optimization

Stamping Higher Strength Steels

Design for Manufacturability (DFM)

Die Maintenance Practices

Problem Solving & Troubleshooting

CONSULTING SERVICES

Technical Consulting

Expert Witness Testimony

ABOUT US

Pace Technologies was founded by Peter Ulintz

in 2008 to provide technical training and professional consulting services to the metal stamping and tool & die industries.

ADDITIONAL INFORMATION

regarding technical training, professional consulting, or other services, contact:

Pete.Ulintz@PaceTechConsulting.com

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.